Test Report

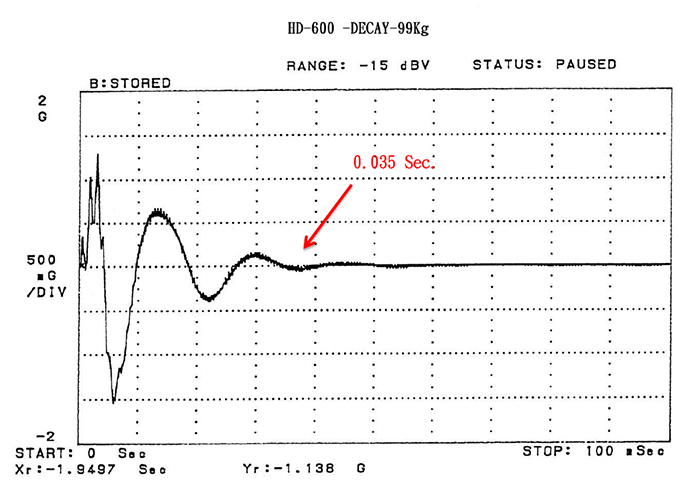

SHOCK ABSORPTION Test Report of High Damping Material & Mounts

- Introduction:

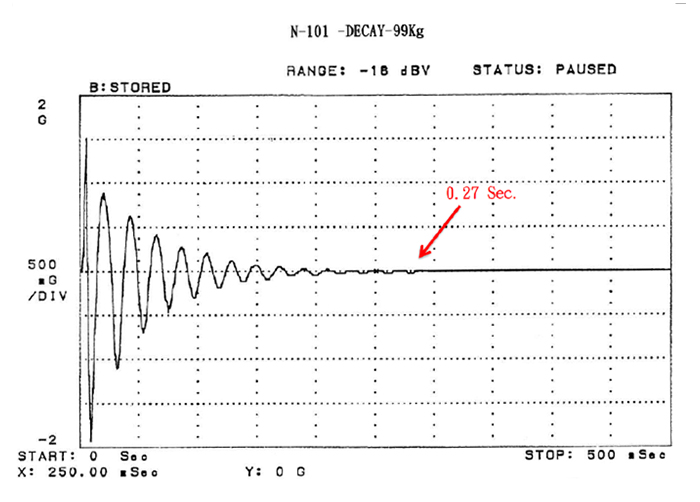

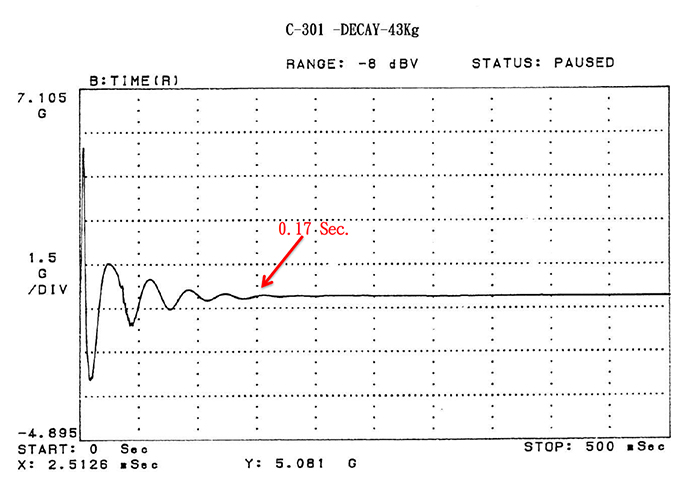

- We have 5 different test piececs for shock absorption test. They are HD-800、HD-600(made from our Hai-Damp® rubber)、N101(made from NR )、0201(Made from NBR) and C301(made from IIR).

- Testing instruments:

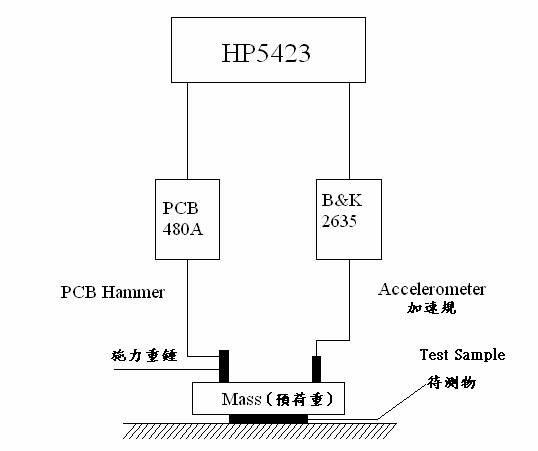

- HP 5423 Structural Dynamics Analyzer

- B&K 4366 Accelerometer(4.81PC/ms-2)

- B&K 2635 Charge Amplifier

- PCB 480A Power Unit

- PCB 205M08 Impluse Hammer Kit(0.5mv/lb)

- Testing method:

- Testing device and diagram:

- After the knocking on the mass ,we can get the test result. (test data and some calculated data are all listed below )

- Testing device and diagram:

- Test results:

- Remarks:

- This test was executed by “ Industrial Technology Research Institute “ in Taiwan. (Test report No.:F78L151)

- HD-800 is our product(Hai Damp®) ,Hardness range 80~85 ˚A and HD-600 is our product(Hai Damp®),Hardness range 60~65 ˚A.

- N-101 is Natural rubber plate, Hardness range 60~65 ˚A.

- O-201 is NBR (oil resistant rubber ) plate, Hardness 60~65 ˚A.

- C-301 is IIR ( Butyl rubber ) plate, Hardness range 55~60 ˚A.

- HD-800、HD-600 series products are made from special syntheticrubber compounds. They have special high damping ratio,high temperature durability (110 ℃ for long term service) and oil resistant properties.(Under exposure to lubricant,greases, and even gasoline and diesel, HD–series product will not swell and they will perform as usual)

- Remarks:

Dynamic properties of various material pieces (All are prepared by compression molding )

- Remarks:

- This test was executed by “ Chung–Shan Institute of Sience &Technology “ in Taiwan.

- This test result reveals the truth :Damping ratios(tanδ) of Hai Damp® series material are similar to that of S brand(an European brand),and are superior to others .

Dynamic and Static Properties of various Vibration Mounts

- Remarks:

- This test was executed by “ Chung–Shan Institute of Sience &Technology “ in Taiwan.

- TK12080 and Febrica52224 mounts are products of local companies in Taiwan.

- From this test result, we can get the conclusion: Hai Damp®-800 vibration mount has the best Damping ratio in the above test.